Specialist Vegetable Machinery Service Department

The Burdens Group Specialist Vegetable Machinery service department can provide service and repairs to all the machines we supply.

We have a team of service technicians who are all factory trained and have fully equipped service vans so that we can carry out any repairs in situ.

With over 70-years experience we can advise on any service-related issues and will travel across the UK and into Ireland to carry our repairs.

We use the latest tooling to ensure that we can swiftly deal with any problems to keep downtime to a minimum.

Key skills of our staff include welding, fabrication work, jump grader servicing and the manufacture of jump grader riddles.

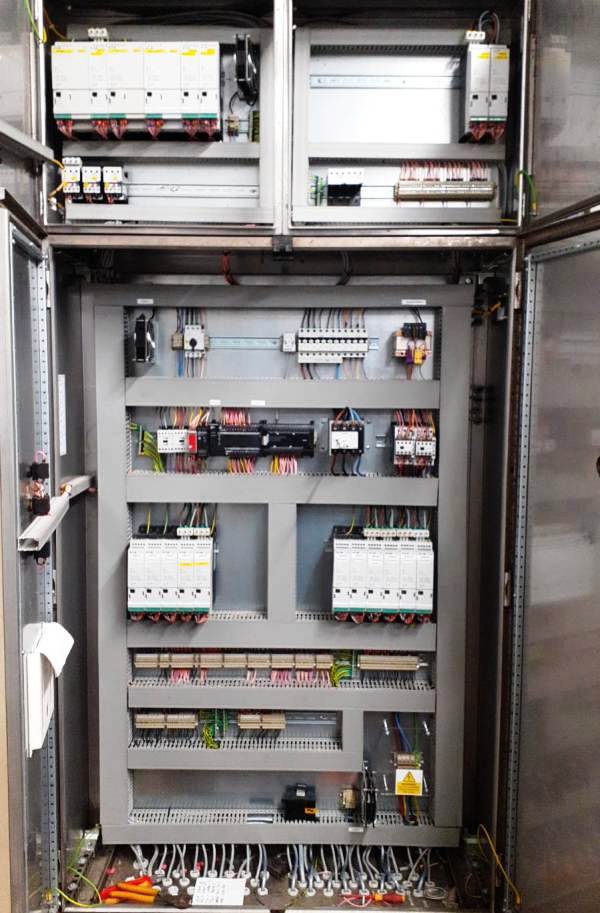

PLC and Electrical Work, Diagnostics and Support

We can also provide programming of PLC’s, design and manufacture control panels, support and fault diagnosis on motor drives and speed control systems. These include TASC, DC and inverter motor speed control systems.

The image above shows an electrical control panel with PLC controlled Eaton inverter variable frequency drives for motor control in vegetable processing lines.

Tong EasyClean Retrofit

We can also carry out the retro-fit of the Tong EasyClean into any make of older grader. This can replace a star cleaning system or a coil cleaner. Fitting one of these will mean cleaning performance can be greatly increased.

In the image below you can see a Tong EasyClean cleaner that has been retrofitted into an older Tong Caretaker grader to improve the extraction of soils from the potato crop.

Give your grader a new lease of life by fitting a new cleaner and see for yourself how the EasyClean can extract soil and clods much more efficiently than a star or coil cleaner. You can also go one step further and fit a presentation conveyor between the hopper and cleaner.

This will thin out the crop and give the cleaner an easier time to deal with soil, clods and haulm.

The EasyClean is also self-cleaning to a point, so it allows the process to keep running when coil and star cleaners would have blocked up with mud.

Belting Repairs and Supply

We can supply and repair conveyor belts and endless belts if the machine can be stripped down so the belt can be fitted. If this is not practical, then the belts can be joined onsite by fitting a vulcanised joint. This can be quicker and more convenient than a strip down.

We can also offer full refurbishment of old belts and provide mechanical and electrical belts.

We can attend on site to replace joiners in situ, or you can bring your belt to us, and it can be done in our workshop. Belting material is kept in stock so damaged belts can be quickly repaired by fitting a new piece of material with an extra joiner.

The image below shows a feed elevator fitted with a food grade PVC flighted belt with corrugated sidewalls.

If you are unsure of exactly what you need, we can visit your site to advise and measure your existing belt.

This service is for customers who are located within 50 miles of our base near Boston in Lincolnshire.

Other Services

We have a coded welder who has experience in manufacturing and alteration of existing equipment. We have recently modified a salad harvester and two vegetable rigs. We can undertake alteration work to all types of grading line irrespective of the make. Please contact us to discuss your requirements.

We can provide service on the Newlong NP7 stitcher and the Fischbein ECR stitchers. This can be carried out in our workshop or be on-site based. In addition, we still support Walthambury stitching and weighing lines.

We carry parts in stock for this type of equipment to help reduce downtime and have the expertise to sort most problems. We can reset topping up times and adjust final weights to improve weigher operation. Service to the Walthambury Bag Automators is still provided and many parts can be obtained from stock including pneumatic cylinders, valves, regulators and fittings.

This has been our main service business for many years. In addition to our main Tong Engineering and Swift Lift franchises we can handle most makes of grading equipment. From simple breakdowns to more complex refurbishments, we can provide a wide range of service and maintenance. The electrical department can get your machine going quickly whatever the problem, from changing panel switchgear to motor, inverter and PLC faults.

For any further information on our range of specialist vegetable machinery service back up please contact us.